© John Sondeyker

© John Sondeyker

PROJECT INFO

Building type:

Offices

Year:

2015

Project Status:

Built

Gross Area:

2800 Sqm

Certificates:

BREEAM New Construction 2011 (UK) Outstanding

Climatic zone:

Temperate

MY LAST SEEN PROJECTS

PROJECT DESCRIPTION

Geelen Counterflow is specialized in counterflow dryers and coolers for the food and feed industry. The family business was established in 1980. R&D, engineering, production and assembly take place in Haelen, the Netherlands.

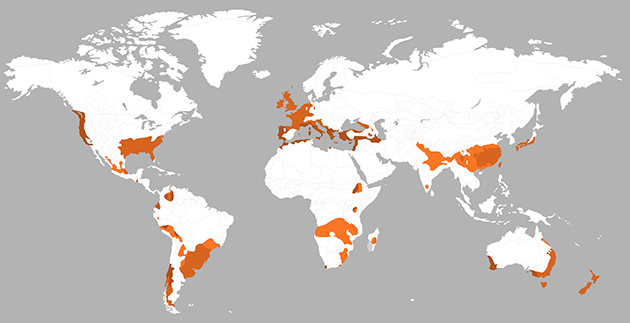

Most machines are exported, mainly outside of Europa. The company has delivered over 7500 machines in more than 100 countries. Geelen Counterflow dryers and coolers are more energy efficient than alternatives, with higher standards of hygiene.

The previous accommodation consisted of over 10,000m2 of production workshops and approx. 650m2 of offices. Over the years, the company has experienced steady growth and a step-by-step expansion of the production workshops. A new wing was also added to the current office building.

The company expects to see further growth in the near future. The capacity of the new office is geared to the expected growth of the workforce over the coming 10 years.

The new building must accommodate 50 office workplaces and include facilities for 90 workers in the production workshops. In view of the close relationship between production and engineering, the workplaces are located near each other.

The new office building must optimally facilitate the work processes. Interaction between the employees is an essential element here. To ensure a pleasant work environment, the new building must offer sufficient daylight, a pleasant view and acoustic comfort, and the new office must offer sufficient openness.

Additionally, to stimulate interaction between office and production personnel, the distinction between office and workshop is limited to a minimum in the design. All personnel and visitors will be able to access the building via its main entrance.

In addition to office spaces for 50 employees, the new building includes supporting office functions like a reception area, meeting rooms, interview rooms, print rooms and toilets. It also includes a large cafeteria for all personnel. An outdoor space in the form of a covered patio is accessible via this cafeteria. The new building will also include a washing and changing room for the workshop personnel.

The location of the different functions in the new building were largely decided on the basis of the logistics flows. 'Passenger traffic' from and to the adjoining productions halls was also an important factor. The locations of the different building functions were mainly decided based on the aim of minimising the risk of contamination, physical contact between workers and based on the transport of goods.

AWARDS

SUSTAINABILITY FEATURES

Photovoltaics

Sustainable building materials

100% energy generated on-site

Daylighting maximised

SUSTAINABILITY STRATEGY

SUSTAINABILITY MEASURES

The ambitions for the new office building's sustainability aspects were very high. On an annual basis, the building functions as an EnergyPLUS office and has a sustainable design. In this document, 'energy usage' or 'energy consumption' refers to both building-related (heating, ventilation, etc.) and non-building-related (lighting, PCs, etc.) energy usage. All sustainable energy production was achieved within the project's plan limits. The adjoining production halls were not taken into consideration here.

STRUCTURE

The first structural measures that were taken in order to achieve these ambitions include high thermal insulation values in combination with an airtight construction.

DAYLIGHTING

The design includes large and high window openings, which allow daylight to reach deep into the building. Three skylights in the roof provide sufficient daylight at the centre of the building. This results in a lower energy demand.

ENERGY

The energy production is completely sustainable. No fossils fuels are used and all energy is generated on site via geothermal and solar energy. The heat and ventilation systems are demand driven. This means that no more energy is used than is needed.

SUSTAINABLE MATERIALS

In designing the office building, a lot of attention was paid to applying sustainable materials. This applies to the main bearing construction and wall materials, but also to the finishing materials used in the building's interior. The choice to use sustainable materials played an important part in receiving the BREEAM ‘outstanding’ score.

Additionally - to the extent that this was possible - the use of construction materials is based on the 'Cradle to Cradle' principle. This implies that they consist of raw materials that are not harmful to the environment, and are recyclable at the end of their life.

The solid wooden bearing construction proved to be the decisive factor in terms of sustainability performance. Wood stores CO2 and also retains it once it has been converted into NUR-HOLZ panels. The production is an energy-low process. The wood was cut in the Black Forest in Germany and did not need to be transported over a long distance.

NUR-HOLZ is 100% recyclable, both in the biological and technological cycle. By using NUR-HOLZ it is possible to achieve a truly sustainable construction. The systems scores high values in terms of energy savings, CO2 reduction, raw material usage, recyclability, lifespan and health.

Wood stores heat slowly and gradually emits it again; this results in an even indoor temperature. Because of its natural look, people tend to feel more comfortable when wood is used in the construction. Wood breathes and creates a natural moisture balance in the building.

To limit any potential damage to ecosystems as a result of the new development, an ecological survey was conducted on and around the construction location. The aim is to minimise the negative impact of the construction activities, and to compensate them where necessary. To this end, a various ecological measures were taken. These include bat boxes, bird nest boxes and insect hotels that are integrated into the external wall of the building, the construction of a natural pool and selecting various plant varieties.

ENERGY DATA

Energy consumption:

21.50 KW/m² (6.815 KBtu/ft²)

Consumption type:

Simulated

Annual carbon footprint:

N/A (N/A )

Climate zone:

Temperate

Min. temperature =

N/A

Max temperature =

N/A

RH =

N/A

CLIENT

Client:

Getec Beheer BV - Haelen

DESIGNERS

Architect:

ARCHION .

Architect:

ARCHION .

CONSULTANTS

Acoustical consultant:

Bureau Geluid - Houthem/Valkenburg , Bureau Geluid

Building services engineer:

Dubourgraaf

Environmental consultant:

Laneco

Manager:

Wagemans Bouwadviezen & Bouwmanagement BV - Sittard , Wagemans Bouwadviezen & Bouwmanagement BV

Other:

Laneco - Ede [Ecologist] , Natuur bij Huis - Lerop [Garden Design]

Specialist consultant:

Dubourgraaf - Goes [Installation Consultant] , Natuur bij Huis

Structural Engineer:

Adviesbureau Lüning

CONTRACTORS

Contract Services:

Derbipure , Drywood Woodstain

Supplier:

MOSO , Accoya , Rockfon Krios , Mosa , Nora , Interface , Kingspan , Drywood Woodstain , Derbipure , AGC , NurHolz

OTHER PROJECTS BY TEAM

SIMILAR PROJECTS

Avenida República do Chile - Centro, Rio - Rio de Janeiro, Brazil | 2013

.jpg)

.png)

Via Filippo Turati, 25, 20121 Milano, Italia | 2012

Via Energy Park, 20871 Torri Bianche MB, Italy | 2009

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Seattle, WA, USA | 2012

.jpg)

Via Umberto Forti, 1, 56121 Montacchiello PI, Italia | 2016

.jpg)

Via Chiese, 72, 20126 Milano MI, Italia | 2018

.jpg)

Viale della Liberazione, 20124 Milano MI, Italia | 2017

.jpg)

Via Bernina, 12, 20159 Milano MI, Italia | 2012

.jpg)

New Cairo City, Cairo Governorate, Egypt | 2016

Parma, Province of Parma, Italy | 2018

.JPG)

.png)

Manhattan, New York, NY, USA | 2016

Via Fabio Filzi, 29, 20124 Milano MI, Italia | 2015

Piazza Tommaso Edison, 20123 Milano MI, Italia | 2017