© Richard Stonehouse / WWF-UK

© Richard Stonehouse / WWF-UK

PROJECT INFO

Building type:

Mixed-Use

Year:

2013

Project Status:

Built

Gross Area:

3675 Sqm

Certificates:

BREEAM 2008 UK Bespoke Outstanding

Climatic zone:

Temperate

MY LAST SEEN PROJECTS

PROJECT DESCRIPTION

The Living Planet Centre is at the forefront of sustainable design and construction. The building is one of the greenest buildings in the UK, showing how it’s possible for people to live in harmony with nature.

The Building:

the Living Planet Centre, designed for WWF-UK by Hopkins Architects, sits on a raised platform beneath an overarching curved roof. Behind its visitor centre the building opens to a two-storey workspace centred on a full height atrium. Constructed by Willmott Dixon with a specialist team committed to the highest standards of sustainable construction, WWF’s new 3600m2 building is well on course to achieve the highest level of environmental performance, BREEAM Outstanding status.

The Living Planet Centre’s 80m arched diagrid roof features photovoltaic panels for solar energy and extensive glass to maximise natural light; four specially-designed recycled aluminium wind cowls provide natural ventilation as air circulates through the building. The water management system includes rainwater harvesting and recycling; ground-source heat pumps mean less energy is used for heating or cooling the building, and there is extensive use of sustainable technologies.

Importantly, the materials used in construction were sourced responsibly, with recycled materials where possible: all wood for the Living Planet Centre comes from responsibly managed forests and some of the refurbished technology was originally used to power the London 2012 Games.

The ground-level landscaping around the building features a wildlife pond, hedgerow and native plant species, most of the original large trees on site being retained. The greenery extends to the platform of the building, and even the new bicycle sheds have a natural sedum roof. The Living Planet Centre is located between a canal and woodland on the edge of Woking.

The WWF Experience:

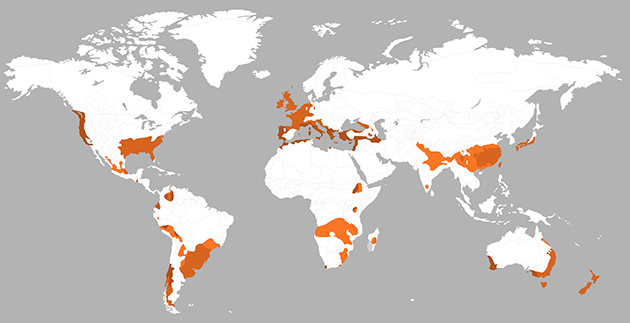

immediately inside the entrance visitors will find four interactive, habitat zones focusing on forests, rivers, oceans and wildlife, interwoven with WWF’s work around the world and showing how people are intrinsically linked with the natural world. Designed collaboratively by Jason Bruges Studio, WWF with assistance from Conrad Partners, each zone evokes the sights, sounds, scents and ambiance of their diverse natural environments, including specially commissioned films and soundtracks. Quotes inspired by nature are etched into the wooden fins forming each structure, and concealed LEDs use light in harmony with the music from hidden feonic speakers to create a unique experience.

Each habitat has its own story: for Forests, a 24-hour cycle from night to day. The freshwater story is told from ‘micro to macro’ - small droplets to great Rivers. ‘Cold to warm’ is the theme for Marine life, from the arctic to tropical seas. The Wildlife zone brings to life the magnificent diversity of species. ‘Trigger’ buttons in each zone, including some cast in bronze from real features of the natural world, allow visitors to interact with their surroundings.

AWARDS

RIBA NATIONAL AWARD 2015

RIBA SOUTH EAST AWARD 2015

RIBA SOUTH EAST SUSTAINABILITY AWARD 2015

BCO Awards 2015 - National winner Innovation

BCO Awards 2015 - Regional winner Corporate Workplace

SUSTAINABILITY FEATURES

Natural ventilation

Innovative cooling system

Shading system

High efficient façade

Photovoltaics

Rainwater harvesting

Grey Water Recycling

Water-saving sanitary appliances

Reclaimed materials

Recycled materials

Low-emitting materials and finishes

Sustainable sourced timber

Smart design (passive design strategies)

Ground Source Heat Pump

Regional materials

Daylighting maximised

SUSTAINABILITY STRATEGY

DESIGN AND CONSTRUCTION

- Our ambition for the Living Planet Centre was to break new ground in carbon emissions

reduction and ensure that the building was an exemplar of low-carbon office design. To do

this, we needed to analyse the embodied CO2e (carbon dioxide equivalent) emissions of all the

materials used in the design and construction process and the ‘whole life’ emissions over a 60-

year period.

- We reduced the embodied whole life carbon emissions by 42% over the duration of the

building project – at no additional cost. This amounted to over 5,400 tonnes of CO2e.

- Where possible, we achieved savings by using recycled materials or local sources. For

example:

+ use of GGBS (ground granulate blast-furnace slag – a by product of iron and steelmaking)

and recycled aggregate in concrete

+ over 80% recycled content in aluminium

+ recycled content used in steel reinforcing

+ 98.9% of building elements classed as Responsibly Sourced by the BRE

+ concrete sourced from local company Cemex.

- The roof’s barrel vault design with interconnecting beams makes it very strong and the glazing

allows natural light into the building. It uses less materials than conventional roof designs and

these materials are lower in carbon, e.g. responsibly-sourced timber rather than concrete.

- To help regulate the temperature of the building in both summer and winter, a product called Energain (recycled aluminium and wax) was built into the roof to provide thermal mass.

- Brise soleil, external structures – made from larch – shade the building from sunlight to

reduce solar gain.

- Internal automated blinds provide solar shading, important for keeping the building cool in

the summer.

ELECTRICITY

- 410 solar panels on the roof (covering 510m2) provide up to 20% of the building’s electricity.

- Thameswey Energy, supplies the remainder of our electricity from their combined heat and power (CHP) plant .

- Electricity generated from the solar panels, that we don’t use, will be fed back to Thameswey in exchange for a payment equivalent to the feed-in tariff (FIT).

HEATING AND COOLING

- Ground source heat pumps (GSHP) will provide both heating and cooling to the building, taking advantage of the relatively constant 12-13oC temperature below the surface of the earth.

- There are 20 bore holes going down 100m and around 400m of earth ducts underneath the building.

- GSHP are powered by electricity, we have no other energy supply to the building.

- GSHP are considered a low carbon technology because they produce more energy as heat than they use as electricity; GSHP can produce 3 to 4 units of heat for every one unit of electricity.

VENTILATION

- Natural ventilation is used in the building where possible.

- Four wind cowls (each 4m tall) on the roof provide a way for air to flow out of the building.

- A green-and-red light system on the perimeter windows indicates when it’s the optimum temperature to open or close them.

BUILDING FIT-OUT

- The carpet in the Living Planet Centre is made from 100% recycled nylon by Biosfera. The yarn used to make the carpets comes from industrial waste sources, such as recycled fishing nets and fluff from old carpets.

- Timber in the furniture comes from credibly certified sources, including with FSC Chain of Custody.

- The building is lit with energy-efficient fluorescent and LED lights. Triggered by movement sensors, they automatically switch off when not in use.

- IT infrastructure incorporates technology used in the London 2012 Olympic and Paralympics Games.

WATER AND DRAINAGE

- To reduce the amount of mains water we use, we’re recycling greywater from hand basins and showers, and harvesting rainwater to flush our toilets and water the plants.

- Excess rainwater collected from the roof drains into the wetlands area as part of our sustainable urban drainage system (SUDS). Once full, the water will discharge into the adjacent Basingstoke Canal.

- The bike sheds and bin store have green roofs covered with sedum mats to encourage biodiversity and reduce the amount of rainwater run-off that would otherwise enter the sewer drains.

BIODIVERSITY

- Local green spaces include the Basingstoke Canal on one side of the Living Planet Centre and Horsell Common, a Site of Special Scientific Interest (SSSI) on the other.

- We’ve established native plant species on the ground level and more exotic species on the podium around the building.

- There are three bat boxes, five bird boxes (including swift boxes) and two bug boxes.

WASTE

- Compost waste from the building produces biogas to generate electricity and residual waste is used as a fertiliser.

- Our intention is not to send any waste to landfill. Any waste that can’t be recycled or composted will be sent for incineration/energy generation.

TRANSPORT

- The building has easy access to Woking train station with regular fast services to London Waterloo.

- There is secure covered storage for 30 bikes, five showers and a drying room. We encourage staff to cycle to work or use public transport wherever possible. 56% of staff are now taking the train to work vs 21% before we moved.

BREEAM

- The building was awarded BREEAM Outstanding rating with a score of 90.5%. Only 24 buildings have reached this standard in the last six years.

- BREEAM is the world’s leading environmental assessment method and rating system for buildings.

- The assessment scores 10 areas of the build: energy, innovation, land use and ecology, management, materials, waste, pollution, transport, water and health and well-being.

ADDITIONAL DATA

Predicted electricity consumption – kWh/m2

26.7 kWh/m2/year for heating, cooling, lighting and hot water

48.17kWh/m2/year for small power (i.e. appliances)

Predicted fossil fuel consumption kWh/m2

65.17 kWh/m2/year

Predicted renewable energy generation kW/m2

9.7 kWh/m2/year (13%)

Predicted water use 2.6 m3/person/year

% predicted water use to be provided by rainwater or greywater 84%

ENERGY DATA

Energy consumption:

N/A (N/A )

Consumption type:

Annual carbon footprint:

N/A (N/A )

Climate zone:

Temperate

Min. temperature =

N/A

Max temperature =

N/A

RH =

N/A

CLIENT

Client:

WWF-UK

DESIGNERS

Architect:

Hopkins Architects

Architect:

Hopkins Architects

Interior designer:

Hopkins Architects

CONSULTANTS

Cost consultant:

Gardiner & Theobald

Environmental consultant:

Atelier Ten

Green certification consultant:

Atelier Ten

Manager:

JEB Project Management , Doherty Baines

Specialist consultant:

Jason Bruges Studio , Sturgis Carbon Profiling , Grant Associates , Cisco , Dimension Data UK

Structural Engineer:

Expedition Engineering

CONTRACTORS

Contractor:

Willmott Dixon Construction

Supplier:

Kinnarps , CISCO

OTHER PROJECTS BY TEAM

SIMILAR PROJECTS

.jpg)

.jpg)

Via Cesare Cantù, 2, 20123 Milano MI, Italia | 2019

Via Cesare Giulio Viola, 68, 00148 Roma RM, Italia | 2015

Via Pietro Borsieri, 2a, 00195 Roma RM, Italia | 2018

Corso Ercole I d'Este, 15, 44121 Ferrara FE, Italia | 2018

.jpg)